Small Scale Bean to Bar Making Equipment and their Impact

Bean to Bar World | 04/30/2019 | Bean To Bar Making Equipment For Small Scale Makers

This is a summary based on the work by Hinneh et al. (2019). For the full article, search the following:

For thousands of years, making chocolate required a metate, a small table-like mortar and pestle. The metate would be placed over a small flame, and cacao beans would be ground into a paste, with the heat from the flame helping to melt the fat from the cacao as it’s being crushed.

Today, large and expensive equipment is used to grind, refine, and fine-tune chocolate into a smooth luxurious product. Even for moderate size chocolate makers, equipment to make the chocolate itself can get started at around $30,000 USD. For chocolate makers who don’t have 30 grand to invest, they require more affordable options.

This research analyzed the various types of equipment suitable for small scale manufacturers, and the impact these machines had on the chocolate. The two main options include a Cocoatown melanger and a Stephan mixer. Both of these are relatively affordable, compact, and more easily accessible.

Overview Of The Experiment

Chocolate was made in three processes, using a mixture of different equipment. Chocolate 1 was made using standard larger scale equipment, including a ball mill to grind and refine the cacao and a conche to fine-tune the chocolate.

Chocolate 3 was made using more affordable smaller scale equipment including a CocoaTown melanger to grind and refine, and a Stephan mixer to act as a conche.

Chocolate 2 was made using equipment from both: the more affordable Cocoatown melanger to grind, and the more costly ELK’olino conche to finish it off.

The results of the equipment focused on:

- Particle size

- Microscopy

- Moisture content

- Particle distribution

- Flow behaviour

Here is a summary I put together of the experiments and the type of equipment used. See below for a visual depiction of the equipment taken from the research article.

The equipment on the far left is the most expensive for larger scale chocolate making. The equipment on the far right is the more economical and more suitable for small scale chocolate making. Image from Hinneh et al. (2019).

Choc 1 = Batch 1, Choc 2 = Batch 2, Choc 3 a-f = Batch 3. Image from Hinneh et al. (2019).

Description Of The Equipment:

Mixers

VEMA & Hobart are both planetary mixers, and were used to combine the ingredients before being refined and conched. The VEMA mixer is temperature controlled, and the ingredients were mixed at 45*C. The hobart mixer is similar, but is not temperature controlled, so it was heated using a heat gun.

3-Roll Refiner

This piece of equipment breaks down the kernel of the seed (AKA cacao nibs). It has two main purposes: to reduce the particle size of the ground up nibs, and to help release the fat (cocoa butter) from within the cells of the kernel. Reducing the particle size under 30 microns will ensure our togue can’t detect the little grains, and it feels smooth. Releasing the fat will help to lubricate the particles within the chocolate and prevent the chocolate from being too viscous or thick.

Here is an image of a 5-roll refiner, and how it works. The spaces between the rollers from bottom to top become smaller and smaller, reducing the particle size. Each consecutive roller spins in the opposite direction of the one next to it, feeding the chocolate up under the next roller. This image was taken from The Science Of Chocolate (Beckett, 2008).

ELK’olino Conche

Once the chocolate particles have been refined small enough through milling, and enough fat has been released, it’s time to fine tune the chocolate flavour. This is done using a conche, first invented in 1879 by Rudolf Lindt in Switzerland.

A modern day conche, such as the ELK’olino used in this experiment, fine tune the flavour of the chocolate via movement and temperature. The back and forth motion of the conche allows the release of aroma molecules into the air. It removes the acidic ones formed during fermentation as well as other aromas, changing the overall flavour of the chocolate.

Heat is added as well, for different purposes. f enough heat is added is said to induce a Maillard reaction, but this is very minimal due to lower water content. Any moisture in the chocolate in this stage is also released, and is said to carry some of the aroma molecules with it. Conching too long basically releases most of the aroma molecules and results in a very bland flat flavour.

CocoaTown Melanger (Roswell, USA)

Image from CocoaTown website.

The CocoaTown melanger was used in place of the the 3-roll refiner. They used both a smaller melanger with cylindrical rollers and a larger melanger with conical rollers.

The melangers can reduce the particle size to under 20 microns, but takes much longer to do so. The 3-roll refiner was able to mill the same amount in 10-15 minutes, where the melanger took 3 (for the smaller melanger) or 4.5 hours for the larger melanger).

It did refine the particle size significantly more than the 3 roll refiner. This is beneficial because reducing the particle size allows for more fat to be released, and protects the cocoa particles and sugar from absorbing more moisture. These particles are hydrophilic, meaning they attract and absorb water. If they are exposed for too long before being covered in fat, they have a higher chance of absorbing moisture, which will lead to a moisture-induced agglomeration. Any added moisture to the chocolate, even just 1%, will thicken the liquid and alter the texture of the final product.

Stephan Mixer (Hameln, Germany)

Image from Stephan website.

The stephan mixer is a multi purpose tool, with rotating blades and a scraper arm to scrape the sides of the bowl. It was used in this experiment to replace the ELK’olino conche. Although the stephan mixer isn’t a conche, it does move the chocolate around like a conche, with attachments to be able to adjust the temperature and pressure.

It has a steam and pressure nozzle to control both temperature and pressure. In this study, longer duration of decreased pressure in the stephan mixer allowed for more moisture removal. It is believed that lowering the pressure lowers the boiling point, therefore allowing more moisture to escape. It is also suggested that this moisture also takes with it aroma molecules, and could help aid the removal of acidic and other unfavorable aromas.

Overview Of How Equipment Impacted The Chocolate

Particle Size Distribution (PSD)

Image from Hinneh et al. (2019).

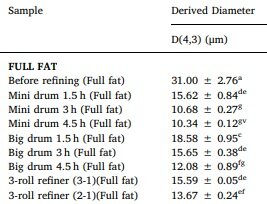

As expected, the longer the refining time, the smaller the particle size. The research compared the PSD between the 3-roll refiner and the melanger. As well, the researchers used two different melangers, a smaller one with cylindrical rollers, and a larger one with conical rollers.

Image from Hinneh et al. (2019).

They observed that the chocolate made from the smaller melanger with cylindrical rollers reduced the particle size more than the larger melanger (Tan and Balasubramanian (2017) found the same results). Looking at the chart here, you can see a starting particle size of about 31 microns. The mini drum was able to reduce the particles to about 10 microns, the big drum reduced the particles to 12 microns, and the 3 roll refiner reduced it to about 13.5 microns. Overall, the melangers reduced the particle size more than the 3-roll refiner did.

Smaller melanger with cylindrical rollers (left), and larger melanger with conical rollers. Image from Hinneh et al. (2019).

The difference between the two melangers likely has to do with the shape of the rollers, with the cylindrical rollers (in the smaller drum) introducing a shearing force, crushing more cocoa and sugar particles. The conical roller (in the larger drum) stones do not introduce a shearing force, and therefore didn’t break down as many cocoa and sugar particles.

The difference between the melangers and 3-roll refiner could be due to the the type of equipment, but as well as the time the cocoa spent in them. The 3-roll refiner was able to complete the process in 10-15 minutes versus 3 and 4.5 hours it took the melangers.

Cocoa liquor (ground up cacao kernel) on the left, and chocolate (cocoa liquor with sugar added) on the right. Image from Hinneh et al. (2019).

Chocolate consists of tiny particles of brown cocoa particles and sugar floating around in fat (cocoa butter). As the nibs or kernel of the cacao seed is ground up, the cell walls are broken and the fat within is released. As the mixture refines and heats up, the fat melts, and lubricates all the tiny broken cocoa particles, as well as the sugar that is being broken down at the same time. The more fat that is available to lubricate the particles, the more loose (less thick) the liquid chocolate becomes. The microscopic image above depicts the cocoa particles, fat, and sugar particles. The tiny starch granules (b) look perfectly spherical and unbroken because they are already under 12 microns or smaller before grinding, and so the crushing of the cocoa kernel doesn’t impact the starch granules.

Moisture Content

Moisture content of chocolate produced from ELK’olino (Choc 1 & 2) and from the Stephan Mixer (Choc 3A-F). Image from Hinneh et al. (2019).

Controlling moisture content is crucial to chocolate making, as it directly impacts the mouthfeel and the viscosity of the chocolate. Too much moisture will cause the chocolate to be too thick when liquid and have a less than desirable texture.

Moisture content for chocolates one and two, which both used the large ELK’olino conche, were at 0.63% and 0.62% respectively. Moisture content from chocolate using the Stephan mixer ranged from 0.52% to 1.03%, depending on the duration of the vacuum pump. The longer the vacuum pump was in use, the greater the amount of moisture was removed. They suggest that the decrease in pressure, which leads to a decrease in the boiling point, helps evaporate the water within the chocolate at a lower temperature. It’s important to note that the moisture content of chocolate from the Stephan mixer and ELK’olino conche were all within the acceptable range of of 0.5-1.5%.

Flow Behaviour

The process of chocolate making has a huge impact on flow behaviour, but ingredients, fat content, and moisture also have a huge influence as well. The flow, or rheology, of chocolate can be measured by yield value. Chocolate is a non-Newtonian fluid which means it requires energy or stress to get it moving. The greater the yield value, the more stress is needed to move the liquid. As you can imagine, the higher the yield value, the thicker the chocolate will be.

Sometimes you want a thicker chocolate, such as to make markings when enrobing. Chocolate that is thicker (higher yield value) will stand up when touched. Sometimes you want a very thin chocolate, such as to cover something in as little chocolate as possible in order to conserve costs. However, when making chocolate, manufacturers often want to achieve a low yield value in order to make the chocolate easier to to use and manipulate.

Below we can see that the different chocolates produced resulted in various yield values. There does appear to be some correlation with moisture content and yeild value.

Chocolate made using the Stephan mixer appeared to have a lower yield value with longer vacuum duration. This also correlated with the moisture content, so it appears the flow and moisture content are directly related. The lower the moisture, the lower the yield value.

The ability for the melanger to reduce particle size smaller and coat more of them in fat seems to have directly reduced the viscosity of the chocolate. The smaller the particle size, the more fat released, and the less the particles are going to impede each other when moving about. The higher fat allows them to flow past each other like a well organized highway, where the cars are particles and the lanes are cocoa butter. Final viscosity appeared to be more related to amount of fat overall in the chocolate.

Conclusion

Hinneh et al. stated that the CocoaTown melanger is a reasonable alternative to the 3-roll refiner for grinding the particle size of the the chocolate, and seems to also grind them to a smaller size. However, the 3-roll refiner is more efficient time wise.

The roller type (cylindrical or conical) in the melanger also had an impact on particle size. The cylindrical rollers were able to produce a greater shear force, which resulted in a smaller particle size.

The Stephan mixer is also suggested to be a favorable alternative to an actual conche. The duration of the vacuum on the Stephan mixer had a significant impact on removing more moisture from the chocolate, and therefore improving the flow properties of the chocolate. However, fat content of the chocolate appeared to have a more important impact on flow.

To read original article: Bean To Bar Making Equipment For Small Scale Makers